Two stage reciprocating compressors offer you more choices of compressor sizes and compressor features to suit your needs.

Multi stage reciprocating air compressor pdf.

Understand the design features associated with the multi stage compressors.

In three stage air compressor fresh air from the atmosphere enters in a first stage low pressure cylinder.

It is known as an indicator diagram for the compressor.

The cylinder head defines a mid stage plenum which is in fluid communication with the low stage cylinder and the high stage cylinder for.

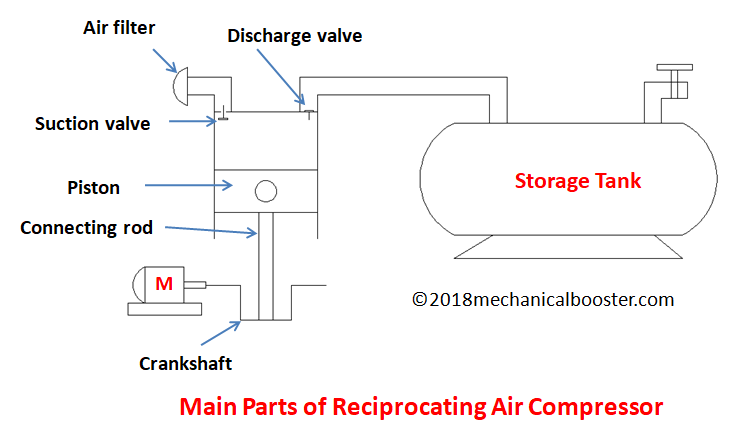

Air enters through a suction filter.

Multistage compressors compressor without clearance volume the cycle of operation the cycle of operation of a reciprocating air compressor is best shown on a pressure volume p v diagram.

If you define unsurpassed performance by maximum operating pressure increased air flow and extended duty cycles count on an ingersoll rand reciprocating air compressor to deliver it reliably.

The cylinder head is secured to the cylinder block overlying the low and high stage cylinders.

Efficient compression particularly with multi stage compressors three step 0 50 100 percent or five step 0 25 50 75 100 percent capacity controls allowing efficient part load operation.

A multi stage reciprocating compressor includes a cylinder block and a cylinder head.

The cycle comprises of three processes.

Working of a single stage reciprocating air compressor calculation of work input volumetric efficiency isothermal efficiency advantages of multi stage compression two stage compressor with inter cooling perfect inter cooling optimum intercooler pressure.

The working principle of multistage air compressor is same as double stage air compressor.

While straightforward this setup is limited in its efficiency and capacity for delivering high volumes of pressurized air.

Two stage reciprocating air compressors are an ideal choice for applications that demand a reliable air supply for everyday use.

Double acting water cooled reciprocating air compressors advantages include.

If we required discharge air pressure above 85 kg cm then four stage air compressors are useful.

Oil lubricated air compressor 160 for multi stage 200 for single stage pure oxygen and pure chlorine 120 dry cylinder with teflon seals 200 other typical standard give maximum temperatur e 150 c for any gas based on adiabatic process.

Whether for vehicle services commercial or industrial applications we will assess and propose the most cost effective solution.

Know about the effects of using a multi stage air compressor with inter cooling.

Stage and gas condition for each stage of gas in reciprocating compressor.

The cylinder block defines a low stage cylinder and a high stage cylinder.